PRINTEC For Quality Rubber Keypad Product Design

Silicone rubber keypads (also known as Elastomeric Keypads) are used extensively in both consumer and industrial electronic products as a low cost and reliable switching solution.

No design limitations on momentary contact switch configuration.

Aesthetics – can be multi-color combination with legends in any color.

Tactile feedback & linear feel optional.

Backlighting keypad design using laser ethching

Contamination proof: due to its physical construction and electrical characteristics, silicone rubber keypads can be free from dust, and it easy isolates contamination.

Special color inks on rubber key-tops guarantee high resistance to corrosion, abrasion and contamination by greases, oil solvents, chemical products and discoloration.

Basic Construction

![]()

Printec manufactures a wide range of custom Silicone Rubber Keypads that provide our customers with non-toxic, elastic long-lasting and dependable products. Our capabilities include:

Multicolored keypads

A wide range of durometers

Dual durometers keys

Screen printing

Laser etching

Robust coatings

Plastic key caps

Dual shot plastic keys

Chroming capabilities

LED windows

A wide variety of shorting pad concepts

• Carbon

• Copper

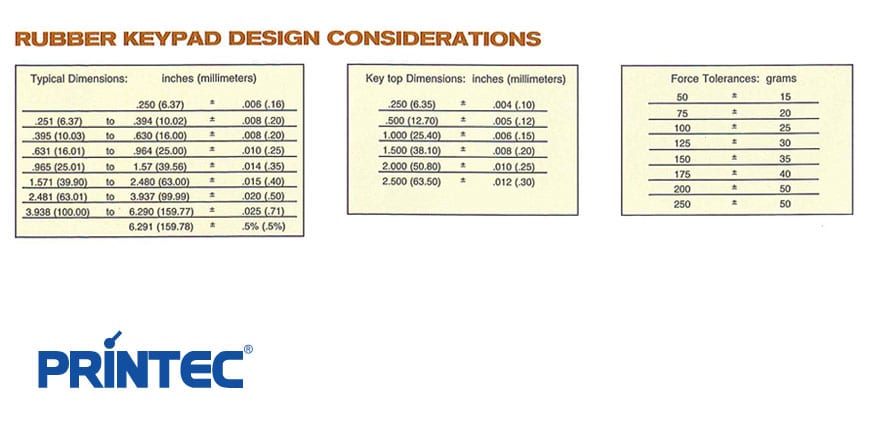

Rubber Keypad Considerations

CONTACT DESIGN

Resistance

Printed Carbon 1,000

Carbon Pill 200 Ohms

Life

Printed Carbon ≤ to 1 million

Carbon Pill ≥ to 1 million

Typically a carbon or gold/nickel plate over copper is recommended if the circuitry is on a printed circuit board. The carbon will have a higher contact resistance with improved immunity to extremely corrosive environments.

NOMENCLATURE LEGEND

Typical nomenclature is applied to the key with various methodologies. Standard printing will meet 250,000 to 500,000 finger activations, before showing signs of wear. To increase cycle life, overcoats can be added. This will increase the life to 1,000,000 activations. In correlating this to the Norman abrasion tester, this will exceed 500 cycles at 500 grams of force.

Legend colors are matched to Pantone Colors with a tolerance of +/- 1 shade. There are printing limitations on the distance between the legend and key edge:

- Silk Screen .5mm minimum from edge of key

- Convex Surface 20mm minimum key radius

- Concave Surface 30mm minimum key radius

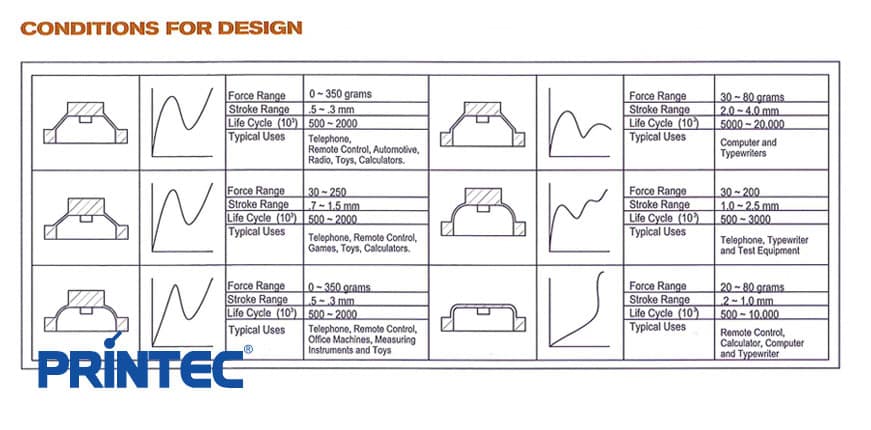

Conditions for Design

Special Designs

![]()

Three Common Constructions of Silicone Keypads

![]()